E-glass Assembled Roving For Chopping

E-glass Assembled Roving For Chopping

Assembled Roving for Chopping e koahetsoe ka boholo bo khethehileng bo thehiloeng ho silane, e tsamaellanang le UP le VE, e fana ka monyetla o phahameng haholo oa resin le ho chopaha hantle haholo, athe lihlahisoa tsa eona tsa ho qetela tse kopaneng li fana ka khanyetso e phahameng ea metsi le lik'hemik'hale tse hanyetsanang haholo le kutu.

Likaroloana

● Ho monyeha ha resin e phahameng

● Ho khabisoa ka tsela e babatsehang

● Ho hanyetsa metsi ho phahameng

● e babatsehang lik'hemik'hale kutu ho hanyetsa lihlahisoa tsa ho qetela

Kopo

Hangata e sebelisoa ho etsa liphaephe tsa FRP.

Lenane la Lihlahisoa

| Ntho | Linear Density | Ho lumellana ha Resin | Likaroloana | Qetella Tšebeliso |

| BHC-01A | 2400, 4800 | PHAHAMA, VE | ho hasana hantle, metsi a itekanetseng a tsoa ka har'a resin, taolo e ntle e tsitsitseng | Liphaephe tsa FRP |

| BHC-02A | 2400, 4800 | PHAHAMA, VE | fuzz tse fokolang, choppability e ntle, khanyetso e ntle ea lik'hemik'hale | joalo ka chop roving bakeng sa tlhahiso ea liphaephe |

| Boitsebiso | |

| Mofuta oa Khalase | E |

| Roving e kopaneng | R |

| Bophara ba Filament, μm | 13 |

| Linear Density, tex | 2400, 4800 |

| Tekheniki Parameters | |||

| Boima ba Linear (%) | Mongobo (%) | Boholo ba litaba (%) | Ho satalla (mm) |

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ±6 | ≤0.15 | 1.20±0,15 | 125±20 |

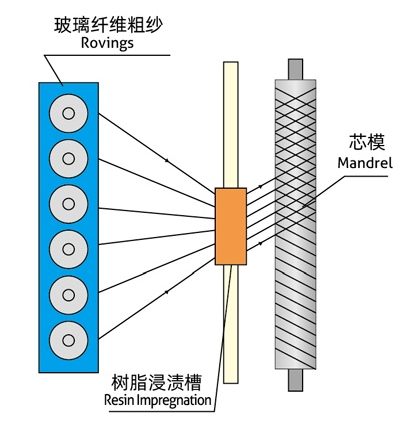

Filament Winding Process

Setso sa Maqhubu a Felisanang

Ts'ebetsong ea khoele ea likhoele, likhoele tse tsoelang pele tsa khalase e kenngoeng ka resin e kenngoa tlas'a tsitsipano holim'a mandrel ka mokhoa o nepahetseng oa libopeho tsa geometri ho aha karolo e phekolehang ho etsa likarolo tse felileng.

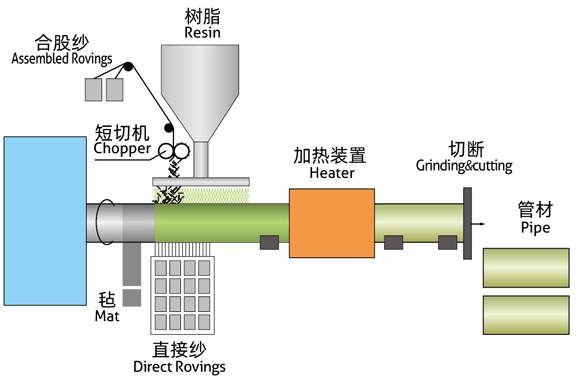

Maqhubu a Tsoelang Pele a Filament

Likarolo tse ngata tsa laminate , tse entsoeng ka resin , likhalase tse matlafatsang le lisebelisoa tse ling li sebelisoa ho mandrel e potolohang, e entsoeng ho tloha sehlopheng sa tšepe se tsoelang pele se tsoelang pele ho tsamaea ka motsamao oa li-cork-screw.Karolo e entsoeng ka motsoako e futhumatsoa 'me e phekoloa ha mandrel e tsamaea ka har'a mohala ebe e khaola ka bolelele bo itseng ka sakha e khaolang e tsamaeang.