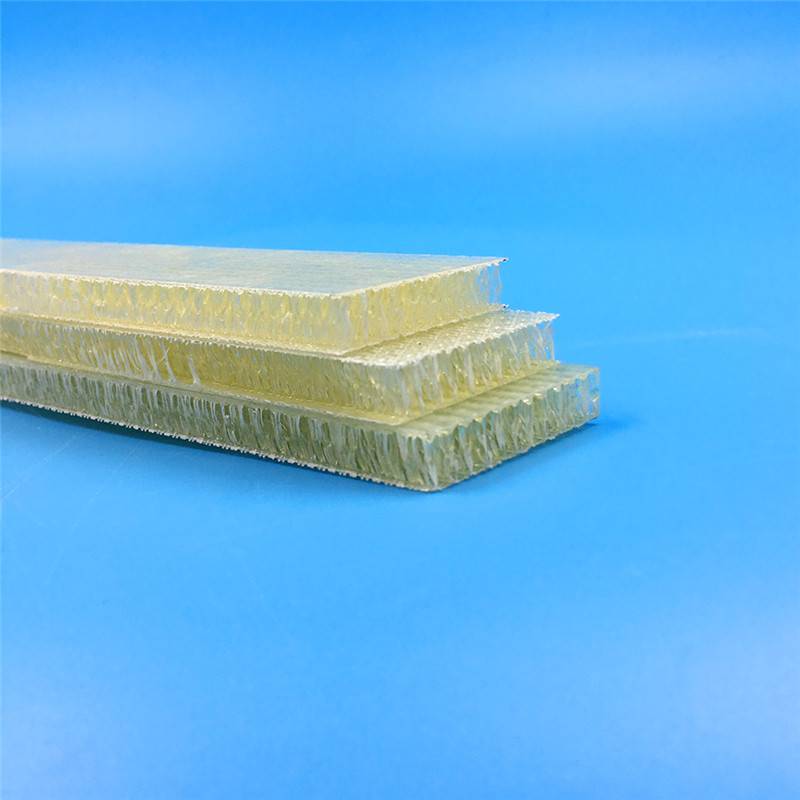

3D FRP Panel e nang le resin

Lesela la 3-D Fiberglass Woven le ka kopanngoa le li-resin tse fapaneng (polyester, Epoxy, Phenolic joalo-joalo), ebe sehlahisoa sa ho qetela ke 3D composite panel.

Molemo

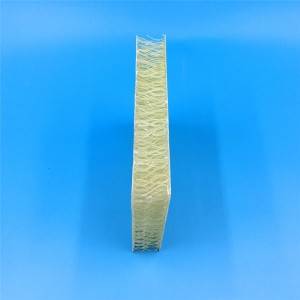

1. boima bo bobebe bur matla a phahameng

2. Khanyetso e kholo khahlanong le delamination

3. Moqapi o phahameng - ho feto-fetoha ha maemo

4. Sebaka pakeng tsa mekhahlelo e 'meli e ka ba le mesebetsi e mengata (E kentsoeng ka li-sensor le lithapo kapa e kenngoe ka foam)

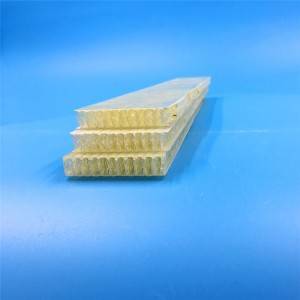

5. Mokhoa o bonolo le o sebetsang oa lamination

6. Mocheso oa ho futhumatsa le ho koala molumo, ho thibela mollo, ho fetisoa ka maqhubu

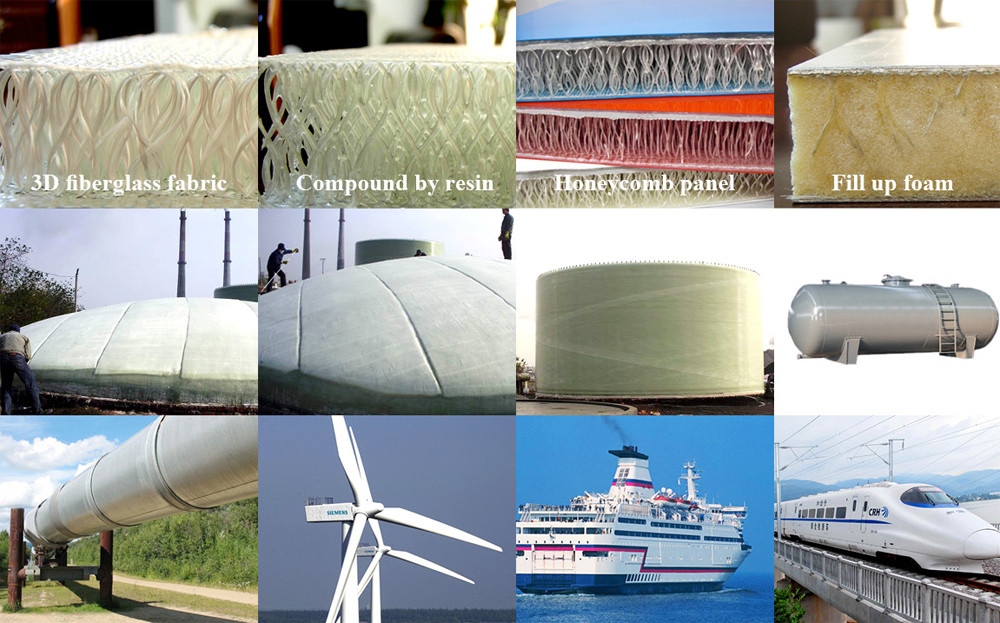

Kopo

Tlhaloso

| Pillar Height | mm | 4.0 | 6.0 | 8.0 | 10.0 | 12.0 | 15.0 | 20.0 | |

| Warp Density | motso / 10cm | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Boima ba Weft | motso / 10cm | 96 | 96 | 96 | 96 | 96 | 96 | 96 | |

| Tekano ea Sefahleho | Masela a 3-D a spacer | kg/m2 | 0.96 | 1.01 | 1.12 | 1.24 | 1.37 | 1.52 | 1.72 |

| Masela a 3-D spacer le kaho ea sandwich | kg/m2 | 1.88 | 2.05 | 2.18 | 2.45 | 2.64 | 2.85 | 3.16 | |

| Flatwise Tensile Matla | MPa | 7.5 | 7.0 | 5.1 | 4.0 | 3.2 | 2.1 | 0.9 | |

| Flatwise Compress Matla | MPa | 8.2 | 7.3 | 3.8 | 3.3 | 2.5 | 2.0 | 1.2 | |

| Flatwise Compressive modulus | MPa | 27.4 | 41.1 | 32.5 | 43.4 | 35.1 | 30.1 | 26.3 | |

| Matla a Shear | Warp | MPa | 2.9 | 2.5 | 1.3 | 0.9 | 0.8 | 0.6 | 0.3 |

| Weft | MPa | 6.0 | 4.1 | 2.3 | 1.5 | 1.3 | 1.1 | 0.9 | |

| Shear modulus | Warp | MPa | 7.2 | 6.9 | 5.4 | 4.3 | 2.6 | 2.1 | 1.8 |

| Weft | MPa | 9.0 | 8.7 | 8.5 | 7.8 | 4.7 | 4.2 | 3.1 | |

| Ho Kobeha Rigidity | Warp | N.m2 | 1.1 | 1.9 | 3.3 | 9.5 | 13.5 | 21.3 | 32.0 |

| Weft | N.m2 | 2.8 | 4.9 | 8.1 | 14.2 | 18.2 | 26.1 | 55.8 | |

Tlhokomeliso: Lenane le ka holimo la ts'ebetso molemong oa tlhahisoleseling feela, ho ipapisitsoe le litlhoko tsa ts'ebetso ea mosebelisi, sebopeho sa matlafatso ea lesela la 3D spacer se ka etsoa.