Khalase ea E e Bokelletsoeng e qamaka Bakeng sa ho Khaola

Khalase ea E e Bokelletsoeng e qamaka Bakeng sa ho Khaola

Ho Roving e Kopantsoeng bakeng sa ho Khaola e koahetsoe ka boholo bo khethehileng bo thehiloeng ho silane, e tsamaellanang le UP le VE, e fana ka ho monyeha ha resin ho phahameng haholo le ho khaoha ho babatsehang, ha lihlahisoa tsa eona tsa ho qetela tse kopantsoeng li fana ka ho hanyetsa metsi ho phahameng le ho hanyetsa ho bola ha lik'hemik'hale ho babatsehang.

Likaroloana

● Ho monya resin e ngata

● E khaoha hantle haholo

● Ho hanyetsa metsi ka tsela e phahameng haholo

● khanyetso e ntle ea lik'hemik'hale ea ho bola ha lihlahisoa tsa ho qetela

Kopo

Hangata e sebelisetsoa ho etsa liphaephe tsa FRP.

Lethathamo la Lihlahisoa

| Ntho | Botenya ba Mothapo | Ho lumellana ha Resin | Likaroloana | Tšebeliso ea ho Qetela |

| BHC-01A | 2400, 4800 | UP, VE | ho hasana hantle, ho kolobisa resin ka tekanyo e itekanetseng, taolo e ntle ea ho se sisinyehe | Liphaephe tsa FRP |

| BHC-02A | 2400, 4800 | UP, VE | fuzz e fokolang, ho khona ho rema hantle, ho hanyetsa lik'hemik'hale hantle haholo | joalo ka ho tjheka ha ho tjheseha bakeng sa tlhahiso ya diphaephe |

| Boitsebiso | |

| Mofuta oa Khalase | E |

| Ho Tsamaea ho Kopantsoeng | R |

| Bophara ba filthara, μm | 13 |

| Botenya ba mola, tex | 2400, 4800 |

| Li-parameter tsa Tekheniki | |||

| Botenya ba Mothapo (%) | Mongobo (%) | Boholo ba Dikahare (%) | Ho satalla (mm) |

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ±6 | ≤0.15 | 1.20±0.15 | 125±20 |

Mokhoa oa ho Phetla Likhoele tsa Filament

Ho Phetla ha Filament ea Setso

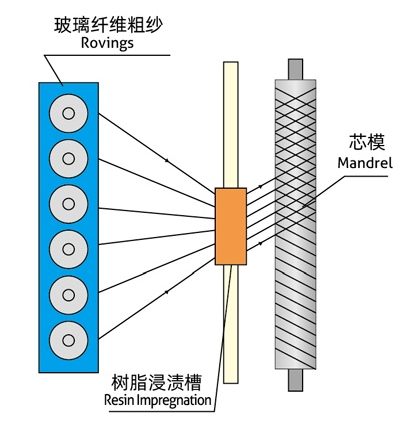

Mokhoeng oa ho kobeha ha khoele, likhoele tse tsoelang pele tsa fiber ea khalase e kenngoeng ka resin li tlamelloa tlas'a khatello holim'a mandrel ka mekhoa e nepahetseng ea jeometri ho haha karolo e tla lokisoa ho etsa likarolo tse felileng.

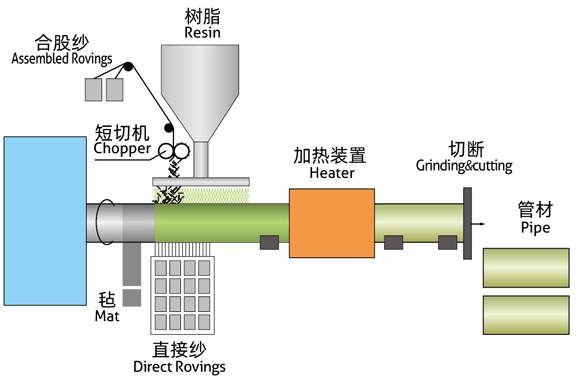

Ho Tsoela Pele ho Phetla Lifilamente

Mealo e mengata ea laminate, e entsoeng ka resin, khalase ea matlafatso le thepa e 'ngoe e sebelisoa ho mandrel e potolohang, e entsoeng ka lebanta la tšepe le tsoelang pele le tsamaeang ka mokhoa o tsoelang pele ka ho sisinyeha ha sekerefu sa kork. Karolo e kopaneng e futhumatsoa le ho hloekisoa sebakeng sa eona ha mandrel e ntse e tsamaea ka har'a mohala ebe e khaoloa ka bolelele bo itseng ka sakha e khaotsoeng e tsamaeang.