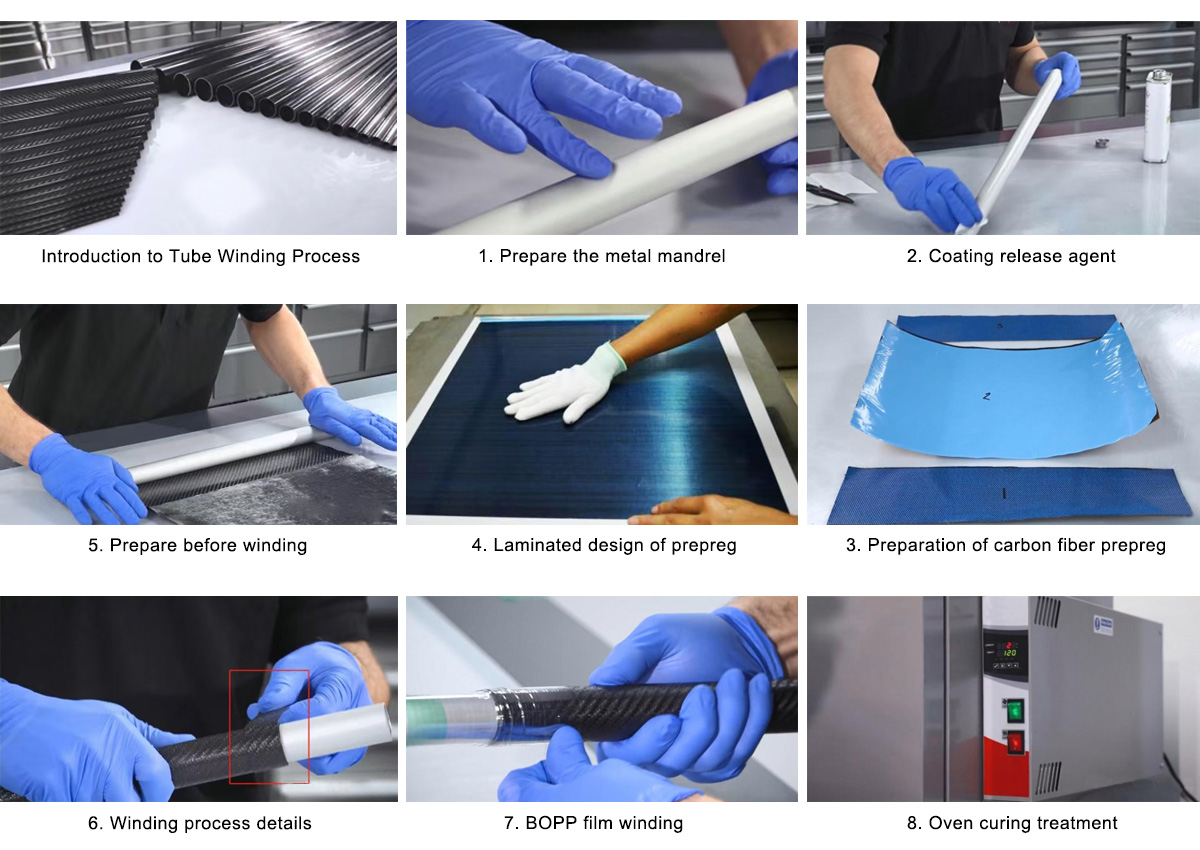

1. Selelekela sa Ts'ebetso ea ho Fetola Tube

Ka thupelo ena, o tla ithuta ho sebelisa mokhoa oa ho thiba lipeipi ho theha meaho ea lipeipi u sebelisa li-prepreg tsa carbon fiber mochining oa ho thiba lipeipi, ka hona u hlahisa matla a phahameng.liphaephe tsa faeba ea carbonMokhoa ona o atisa ho sebelisoa ke bahlahisi ba thepa e kopaneng.

Haeba o lakatsa ho hlahisa diphaephe tse nang le mahlakore a bapileng kapa tse tenyetsehang ka ho tswela pele, tshebetso ya ho thiba diphaephe ke kgetho e ntle. Seo o se hlokang feela ke mandrel ya tshepe ya boholo bo loketseng le onto ho etsa diphaephe tsa khabone tse ikgethileng tse etseditsweng ditlhoko tsa hao tse ikgethileng.

Bakeng sa lipeipi tsa faeba ea khabone tse bōpehileng joaloka tse rarahaneng, tse kang li-handlebar kapa meaho e rarahaneng ea foreimi ea li-tube joalo ka lifereko tsa ho emisoa kapa liforeimi tsa libaesekele, theknoloji ea hlobo e arohaneng ke mokhoa o ratoang. Joale re tla bontša mokhoa oa ho sebelisa theknoloji ea hlobo e arohaneng ho hlahisa lipeipi tsena tse rarahaneng tsa fiber ea khabone.

2. Ho Sebetsa le ho Lokisa Li-Mandrel tsa Tšepe

- Bohlokoa ba Li-Mandrel tsa Tšepe

Pele o qala tshebetso ya ho phunya tube, mohato wa pele ke ho lokisa di-mandrel tsa tshepe. Di-mandrel tsa tshepe di lokela ho lekana le bophara ba kahare ba di-tube, mme boreledi ba tsona ba bokahodimo le kalafo e loketseng ya pele di bohlokwa. Ho feta moo, di-mandrel tsa tshepe di lokela ho feta kalafong e nepahetseng ya pele, jwalo ka ho hlwekisa le ho sebedisa sehlahiswa sa ho lokolla, ho nolofatsa tshebetso e latelang ya ho phunya.

Nakong ea ts'ebetso ea ho phuthoa ha tube, mandrel ea tšepe e bapala karolo ea bohlokoa kaha e tlameha ho tšehetsaprepreg ea fiber ea carbonho netefatsa hore ho kobeha ho boreleli. Ka hona, ho lokisa boholo bo loketseng ba mandrel ea tšepe esale pele hoa hlokahala. Kaha faeba ea carbon e tla kobeha ho potoloha bokaholimo ba mandrel, bophara ba kantle ba mandrel bo tlameha ho lekana le bophara ba kahare ba tube ea faeba ea carbon e tla etsoa.

- Moemeli oa tokollo ea ho etsa kopo

Dintho tse lokollang di fokotsa kgohlano mme di netefatsa hore di a kgaolwa ka boreledi; di lokela ho sebediswa ka ho lekana hodima mandrel. Kamora hore mandrel ya tshepe e lokiswe, mohato o latelang ke ho sebedisa ntho e lokollang. Dintho tse sebediswang hangata di kenyeletsa oli ya silicone le parafini, tse fokotsang kgohlano pakeng tsa faeba ya khabone le mandrel ya tshepe ka katleho.

Ho mandrel ea tšepe e lokisitsoeng, re tlameha ho netefatsa hore e hloekile hantle le bokaholimo bo boreleli kamoo ho ka khonehang ho nolofatsa ho tlosoa ha sehlahisoa ka boreledi. Ka mor'a moo, sesebelisoa sa ho lokolla se lokela ho sebelisoa ka ho lekana holim'a mandrel.

3. Ho lokisa prepreg ea fiber ea carbon

- Mefuta le melemo ea prepreg

Ke di-prepreg tsa carbon fiber feela tse fihlelang ditlhoko tse hodimo tsa ho nepahala ha ho kobeha le bonolo ba ho sebetsana le tsona. Le hoja mefuta e meng ya thepa e matlafatsang, jwalo ka masela a omileng a kentsweng ka epoxy, e ka sebediswa ka kgopolo ya hore tshebetsong ya ho kobeha, ha e le hantle, ke di-prepreg tsa carbon fiber feela tse ka fihlelang ditlhoko tse hodimo tsa ho nepahala le bonolo ba ho sebetsana le tsona tshebetsong ena.

Thutong ena, re sebelisa mokhoa o ikhethileng oa ho beha likarolo tsa pele ho ntlafatsa ts'ebetso ea tube.

- Moralo oa ho Layup oa Pele ho Boroko

Lera la prepreg e lohiloeng le beoa ka hare ho tube, le lateloa ke mekhahlelo e 'maloa ea prepreg e lohiloeng ka lehlakoreng le le leng, 'me qetellong lera le leng la prepreg e lohiloeng le beoa ka lehlakoreng le ka ntle la tube. Moralo ona oa layup o sebelisa ka botlalo melemo ea tataiso ea faeba ea prepreg e lohiloeng li-axes tsa 0° le 90°, e leng se ntlafatsang haholo ts'ebetso ea tube. Bongata ba li-prepreg tse lohiloeng ka lehlakoreng le le leng tse behiloeng mothating oa 0° li fana ka ho tiea ho hoholo ha bolelele ba phaephe.

4. Phallo ea ts'ebetso ea ho potoloha ha liphaephe

- Tokisetso ea ho phutholla pele

Kamora ho qeta moralo oa prepreg layup, ts'ebetso e tsoela pele ho ea ts'ebetsong ea ho phutholla phaephe. Ts'ebetso ea prepreg e kenyelletsa ho tlosa filimi ea PE le pampiri ea ho lokolla, le ho boloka libaka tse loketseng tsa ho kopana. Mohato ona o bohlokoa bakeng sa ho netefatsa tsoelo-pele e boreleli ea lits'ebetso tse latelang tsa ho phutholla.

- Lintlha tsa ts'ebetso ea ho phethoa

Nakong ea ts'ebetso ea ho phethola, ho bohlokoa ho netefatsa hore li-prepreg li phethola hantle, 'me shaft ea tšepe e behiloe ka mokhoa o tsitsitseng le ka matla a sebelisoang ka mokhoa o ts'oanang. Shaft ea tšepe e lokela ho beoa ka mokhoa o tsitsitseng moeling oa lera la pele la li-prepreg, ho netefatsa hore matla a sebelisoa ka mokhoa o ts'oanang.

Nakong ea ho kobeha, li-prepreg tse ling li ka kobeha lipheletsong ho nolofatsa ho tlosoa ha sehlahisoa nakong ea ho se tlosa.

- Ho phuthela filimi ea BOPP

Ntle le ho lokisa pele, filimi ea BOPP e ka boela ea sebelisoa bakeng sa ho phuthela. Filimi ea BOPP e eketsa khatello ea ho kopanya, e sireletsa le ho tiisa prepreg. Ha ho sebelisoa filimi ea ho phuthela ea BOPP, ho bohlokoa ho netefatsa hore litheipi lia kopana ka ho lekaneng.

5. Mokhoa oa ho Phekola Ontong

- Mocheso o Folisang le Nako

Kamora ho phuthela ka thata thepa e matlafalitsoeng ea prepreg carbon faeba, e romeloa ka ontong bakeng sa ho e lokisa. Taolo ea mocheso e bohlokoa nakong ea ho lokisa ka ontong, kaha li-prepreg tse fapaneng li na le maemo a fapaneng a ho lokisa. Mohato ona ke oa bohlokoa bakeng sa ho netefatsa botsitso ba thepa le ho ntlafatsa ts'ebetso.

Ka tikoloho ea mocheso o phahameng ka ontong,faeba ea khabonele resin matrix li arabela ka botlalo, li etsa thepa e kopaneng e tiileng.

6. Ho Tloswa le ho Sebetswa

Kamora ho tlosa filimi ea ho phuthela ea BOPP, sehlahisoa se phekotsoeng se ka tlosoa. Filimi ea BOPP e ka tlosoa kamora ho phekoloa. Haeba ho hlokahala, ponahalo e ka ntlafatsoa ka ho sanda le ho penta. Bakeng sa ntlafatso e eketsehileng ea botle, lits'ebetso tse ling tsa ho qetela tse kang ho sanda le ho penta li ka etsoa.

Nako ea poso: Phato-11-2025