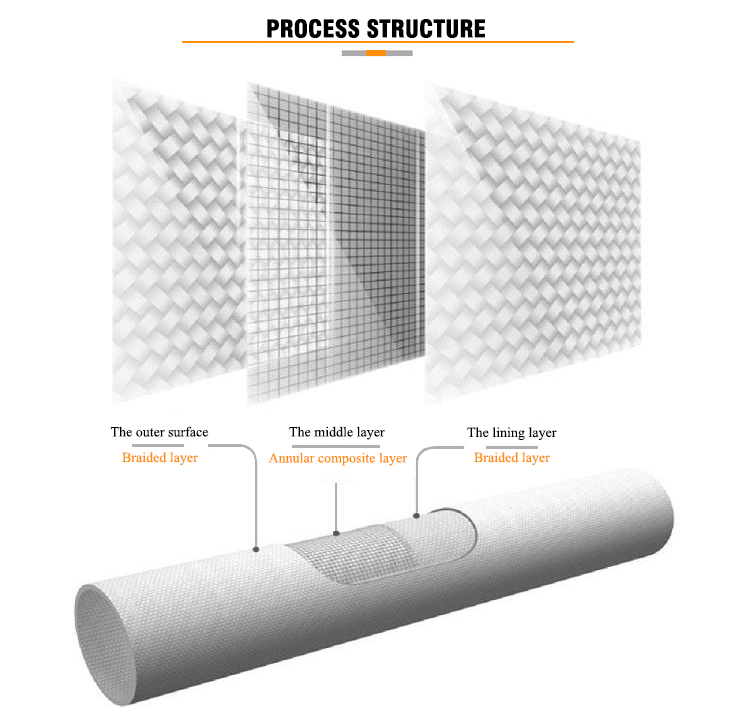

Phaephe ea FRP ke mofuta o mocha oa thepa e kopaneng, ts'ebetso ea eona ea tlhahiso e ipapisitse haholo le resin e ngata ea lera le potolohang la fiber ea khalase ho latela ts'ebetso, E entsoe ka mor'a ho phekola mocheso o phahameng. Sebopeho sa lebota la liphaephe tsa FRP se utloahala haholoanyane ebile se tsoetse pele, se ka bapalang karolo e felletseng ea lisebelisoa tse kang fiber ea khalase, resin le moemeli oa ho phekola, tse sa fihlelleng matla le ho tiea tse sebelisitsoeng feela, empa hape li netefatsa botsitso le ts'epo ea liphaephe tsa FRP.

Litšobotsi tsa tekheniki

1.Tsamaiso ea tlhahiso ea matsoelintsoeke e tsoelang pele

Ts'ebetso ea ho bōpa e tsoelang pele e arotsoe ka mefuta e meraro: ho phethoa ka mokhoa o omileng, ho phethoa ka mokhoa o metsi le ho phethoa ka mokhoa o omileng hanyane ho latela boemo ba 'mele le ba lik'hemik'hale ba matrix ea resin nakong ea ho phethoa ka mokhoa o omileng oa fiber. Ho phethoa ka mokhoa o omileng ke ho sebelisa khoele ea prepreg kapa theipi e phekotsoeng esale pele, e futhumatsoang mochining o phethoang ho e nolofatsa ho ea boemong ba mokelikeli o hlabang ebe e phutheloa holim'a hlobo ea mantlha. Tšobotsi e kholo ka ho fetisisa ea ts'ebetso ea ho phethoa ka mokhoa o omileng ke bokhoni ba eona bo phahameng ba tlhahiso 'me lebelo la ho phethoa le ka fihla ho 100-200m/min; ho phethoa ka mokhoa o metsi ke ho phethoa ka kotloloho sephutheloana sa faeba (theipi e kang khoele) holim'a mandrel tlas'a taolo ea khatello kamora ho qoelisoa ka sekhomaretsi; Ho phethoa ka mokhoa o omileng ho hloka ho eketsa lisebelisoa tsa ho omisa ho tlosa solvent khoeleng e qoelitsoeng kamora hore faeba e qoelisoe ka har'a hlobo ea mantlha.

2.Tsamaiso ea ho lokisa ea ho lokisa ka hare

Ts'ebetso ea ho lokisa ka hare ke ts'ebetso e sebetsang hantle ea ho bopa bakeng sa thepa ea faeba e kopantsoeng ea thermosetting. Hlobo ea mantlha e hlokahalang bakeng sa ts'ebetso ea ho lokisa ka hare ke sebopeho se se nang letho sa cylindrical, 'me lipheletso ka bobeli li entsoe ka taper e itseng ho nolofatsa ho tlosoa. Phaephe ea tšepe e se nang letho e kentsoe ka mokhoa o kopaneng ka hare ho hlobo ea mantlha, ke hore, ho futhumatsa. Bakeng sa tube ea mantlha, pheletso e 'ngoe ea tube ea mantlha e koetsoe, 'me pheletso e 'ngoe e bulehile e le ho kenella ha mouoane. Masoba a manyane a ajoa leboteng la tube ea mantlha. Masoba a manyane a ajoa ka mokhoa o lekanang likarolong tse 'ne ho tloha karolong ea axial. Hlobo ea mantlha e ka potoloha shaft, e leng se loketseng ho kobeha.

3. Sistimi ea ho tlosa mouoane

E le ho hlola mefokolo e mengata ea ho tlosa liphaephe ka letsoho, mohala oa sejoale-joale oa tlhahiso ea liphaephe tsa tšepe ea khalase o entse sistimi ea ho tlosa liphaephe ka boiketsetso. Sebopeho sa mechini sa sistimi ea ho tlosa liphaephe se entsoe haholo-holo ka sesebelisoa sa trolley se tlosang liphaephe, silindara e notlelang, setlamo sa khohlano se tlosang liphaephe, molamu o tšehetsang le sistimi ea pneumatic. Koloi ea ho tlosa liphaephe e sebelisoa ho tiisa hlobo ea mantlha nakong ea ho kobeha, 'me silindara e notleloa nakong ea ho tlosa liphaephe. Molamu oa piston oa huloa, bolo ea tšepe e khomarelang e phahamisitsoeng ka lehlakoreng la mohatla oa mohatla ea beoa fatše, spindle ea lokolloa, ebe litlamo tsa khohlano tse tlosang li phethela ts'ebetso ea ho tiisa spindle ka matla a khohlano a potoloho ea spindle le silindara, 'me qetellong ho notlela silindara le litlamo tsa khohlano tse tlosang liphaephe. Arola 'mele oa tube ho hlobo ea mantlha ka lisebelisoa tse ling ho phethela ts'ebetso ea ho tlosa liphaephe.

Litebello tsa nts'etsopele ea nakong e tlang

Tšimo e pharaletseng ea kopo ea sehlahisoa le sebaka se seholo sa 'maraka

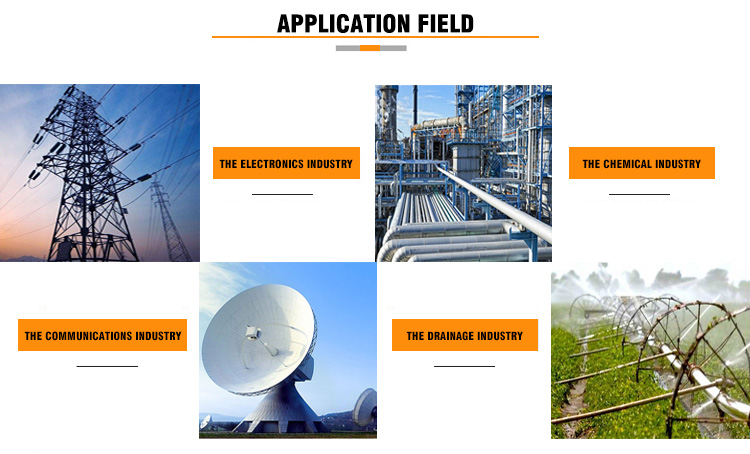

Liphaephe tsa FRP li raloa haholo 'me li ka fihlela litlhoko tsa ts'ebeliso ea masimo a mangata. Masimo a ts'ebeliso a tloaelehileng a kenyelletsa kaho ea likepe, tlhahiso ea lisebelisoa tsa boenjiniere ba likepe, petrochemical, khase ea tlhaho, motlakase, phepelo ea metsi le drainage, matla a nyutlelie, jj., 'me tlhoko ea' maraka e kholo.

Nako ea poso: Mmesa-27-2021