Ho eketsa lifaha tsa khalase tse se nang letho lihlahisoa tsa rabara ho ka tlisa melemo e mengata:

1, Phokotso ea boima ba 'mele

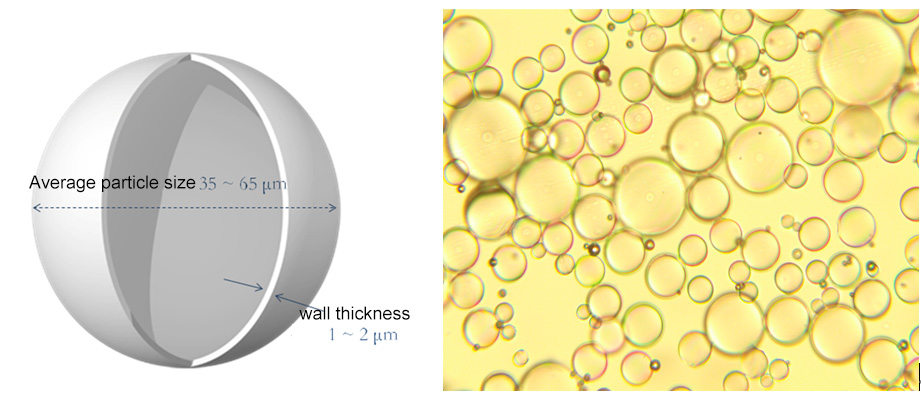

Lihlahisoa tsa rabara le tsona li lebile tataisong e bobebe, e tšoarellang, haholo-holo ts'ebeliso e butsoitseng ea li-microbeads rabara soles, ho tloha ho bongata bo tloaelehileng ba 1.15g/cm³ kapa ho feta, eketsa likarolo tse 5-8 tsa microbeads, tse fokolitsoeng ho 1.0g/cm³ (tse tsejoang ka ho fetisisa e le "ho phaphamala holim'a metsi"), ho na le tekanyo e itseng ea bokhoni ba R & D ba bareki ka ho eketsa microbeads e tla ba boima ba 0.9 kapa esita le 0.85g/cm³, e leng ho fokotsang haholo boima ba rabara, lieta le boemo bo tšoanang pele ho fokotseha ha boima ba 20% kapa ho feta. Hona joale, bareki ba bang ba nang le bokhoni bo itseng ba R & D ba tla etsa hore bongata ba 0.9 kapa esita le 0.85g/cm³ ka ho eketsa microbeads, e leng se fokotsang haholo boima ba rabara, 'me boima ba lieta bo tla fokotseha ka hoo e ka bang 20% tlas'a boemo bo tšoanang le ba pele.

2, ho kwahela mocheso

Sebopeho se sekoti sa difaha tsa khalase tse sekoti se fa difaha mokgahlelo o tlase wa mocheso, kaha setlatsetso se tlase sa motlakase se ekelitsoeng ho thepa ya rabara se ka bapala phello e ntle haholo ya mocheso, jwalo ka dipading tsa ho thibela mocheso, diboto tsa ho thibela mocheso le dihlahiswa tse ding tse sebediswang.

3, Ho monya molumo le phokotso ea lerata

Ka hare ho lifaha tsa khalase tse se nang letho ho na le khase e tšesaane, maqhubu a molumo karolong ena a tla fokola, ka tekanyo e itseng ea ho eketsa ho bapala phello e ntle haholo ea ho monya molumo le phokotso ea lerata.

4, botsitso bo botle ba tekanyo

Thepa ea motheo ea lifaha ke khalase e nang le coefficient e tlase ea katoloso ea mocheso, botsitso bo botle ba litekanyo ha bo hlaseloa ke mocheso, bo eketsoang thepa ea rabara bo tla fa sehlahisoa botsitso bo betere ba litekanyo.

Litlhahiso tsa tšebeliso ts'ebetsong:

1, disebediswa tsa ho lokisa dihlahiswa tsa rabara hangata di teteaneng, di butswe, di-extruder tse nang le nsete e le nngwe, jj., hobane difaha ke tsa dibopeho tsa khalase, lebota ke la dikarolwana tse thata, mme matla a ho kuta a tla robeha hanyane, difaha di tla lahlehelwa ke tshebetso ya tsona e ikgethang ka mora ho robeha.

2, lifaha tsa khalase tse se nang letho li na le mehlala e fapaneng le liparamente tse tsamaellanang, ho latela litlhoko tse fapaneng tsa lisebelisoa le sehlahisoa ho khetha lihlahisoa tse nepahetseng tsa lifaha ke tsa bohlokoa haholo, St. Leite e khothaletsa tšebeliso ea HL38, HL42, HL50, HS38, HS42 lihlahisoa tsa rabara.

3, ha e sebediswa mochining wa ho hlwekisa, ho na le rotor hodima ho kuta thepa ya rabara, difaha di ke ke tsa qojwa ke matla a ho kuta, kahoo ho fokotsa nako ya difaha ho hlwekiseng, ho kgothaletswa ho eketsa ho hlwekisa morao ho netefatsa hore difaha tse ekeditsweng ho hlwekiseng metsotso e 3-5 di ka hasana ka ho lekana; mochining wa ho hlwekisa, sebaka sa rolara le nako ya ho hlwekisa ya ho sila difaha di na le tshusumetso e kgolo, ho kgothaletswa hore sebaka sa rolara se be ka hodimo ho 2mm, nako ya ho hlwekisa ha ea lokela ho ba telele haholo; Matla a kakaretso a ho kuta a extruder e le nngwe ya sekereforo a manyane, ha re bua ka tsela e batlang e tshwana, tshusumetso hodima difaha tse nyane e nyane, ho kgothaletswa ho eketsa mocheso wa extrusion ka 5 ℃, ho fokotsa viscosity ya thepa ho thusa haholo ho bopa extrusion, ho fokotsa difaha tse nyane tse robehileng.

Nako ea poso: Phupu-21-2023