Hoa utloisisoa hore lebaka leo ka lona terene e nang le mekato e 'meli e sa kang ea eketsa boima bo bongata ke ka lebaka la moralo o bobebe oa terene. 'Mele oa koloi o sebelisa palo e kholo ea thepa e ncha e kopantsoeng e nang le boima bo bobebe, matla a phahameng le ho hanyetsa mafome. Ho na le maele a tummeng indastering ea tlhahiso ea lifofane: "Leka ho fokotsa gram e 'ngoe le e 'ngoe ea boima." Hape litereneng tsa terene tse lebelo le phahameng, litereneng tse ka tlas'a lefatše le masimong a mang a lipalangoang tsa terene, ho bebofatsa ho na le bohlokoa bo ikhethang ba bohlokoa le ba moruo bakeng sa ho fokotsa boima ba 'mele, keketseho ea lebelo le phokotso ea tšebeliso ea matla. Melemo; 'me ts'ebeliso ea thepa e ncha e kopantsoeng e fana ka tiisetso ea bohlokoa ea thepa bakeng sa thepa e bobebe ea kahare tšimong ea lipalangoang tsa terene.

Lekhetlong lena, e 'ngoe ea thepa e bobebe e entsoeng le ho sebelisoa kahare ho thepa ea PC ea polycarbonate ea train-thermoplastic e nang le liketso tse peli, e sebelisoa haholo-holo likarolong tse ka holimo le tse ka tlase tsa kariki le liphanele tsa mabota a lehlakoreng le mahlakoreng le liphanele tsa marulelo a mahlakoreng; ka nako e ts'oanang, Hape ke projeke ea pele ea lehae ea mose ho maoatle ho sebelisa li-composite tsa PC tsa thermoplastic sebakeng se seholo karolong ea bapalami ea EMU; e phethoa ka lits'ebetso tse kang extrusion e hloekileng le e se nang lerōle, thermoforming e se nang khatello e phahameng, ts'ebetso e bohlale ea CNC ea li-axis tse hlano, le ho iketsetsa modular; litlamorao tsa sehlahisoa Ho fihlela litlhoko tsa ho tiea ho hoholo, matte, 'mala o khethehileng le sebopeho sa bokaholimo.

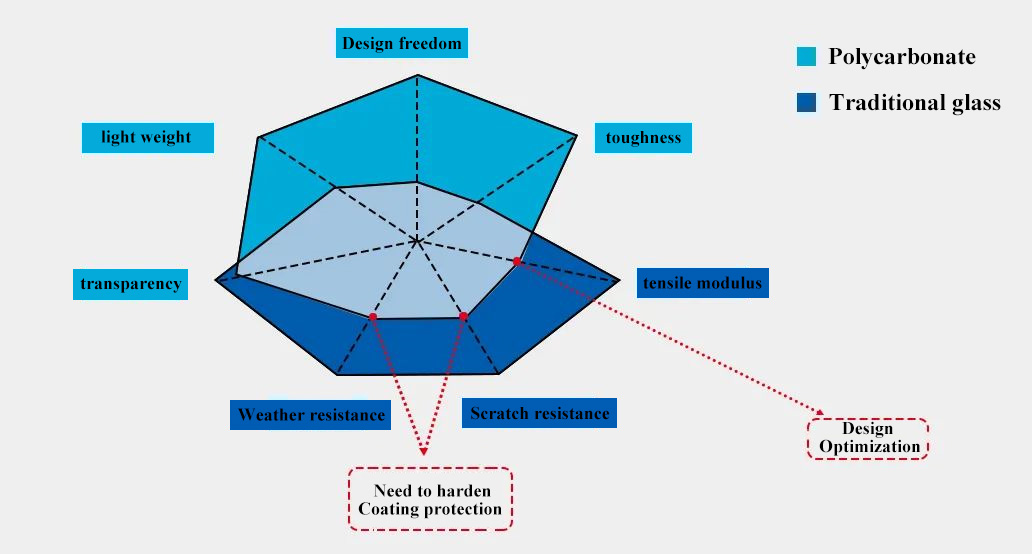

Ha ho bapisoa le thepa ea kahare e kang polasetiki e matlafalitsoeng ka khalase le khalase e sebelisitsoeng hantle ka kamoreng ea ho hlapela 'me e tloaelehile ho sechaba, metsoako ea PC ea thermoplastic e ka ba le kutloisiso ea "sebaka", e leng se bakoang haholo-holo ke mokhoa le morethetho oa nts'etsopele ea thepa e ncha ts'ebetsong ea nts'etsopele ea mehla ea indasteri; Ka tšireletso e tala ea tikoloho le likhopolo tsa nts'etsopele e tsitsitseng ea "plastiki ho e-na le khalase" le "plastiki ho e-na le ho tiea", e le thepa e bobebe e fihlelang litekanyetso tse kholo tsa indasteri, metsoako ea PC ea thermoplastic e ka nolofatsoa ka ho kopanya likarolo. Tlhahiso, ho qoba ts'ebetso ea bobeli, ho sebelisoa hape, le ho fokotsa boima ba 'mele ho etsa hore litšenyehelo tsa lipalangoang, litšenyehelo tsa basebetsi, le litsela tse ling tsa ho fokotsa litšenyehelo tsa sistimi haholo; ka nako e ts'oanang, e ka boela ea fihlela litekanyetso tse thata le tse rarahaneng tsa lefats'e tsa liteko tsa mollo, mosi le chefo; Ka hona, lilemong tsa morao tjena, butle-butle e kene tšimong ea likarolo tsa 'mele oa likoloi tsa literene, 'me e' nile ea ananeloa ka tumellano ke OEMs tse kholo tsa likoloi tsa literene le lifeme tse tšehetsang; ka nako e ts'oanang, indastering ea literene tsa literene Chaena le lefats'e, lisebelisoa tsa PC tsa thermoplastic li qalile ho etsoa ka hare ho naha.

Hona jwale, leqhubu le letjha la boqapi ba theknoloji le emetsweng ke marangrang a tlhahisoleseding, tlhahiso e bohlale, matla a matjha le thepa e ntjha le ntse le hlaha lefatsheng ka bophara, mme potoloho e ntjha ya diphetoho tse akaretsang lefapheng la disebediswa tsa dipalangwang tsa diterene tsa lefatshe ka bophara e ntse e eketseha. Ikamahanye le tataiso e ntjha ya ntshetsopele ya lefapha la tlhahiso le phahameng la dipalangwang tsa diterene, kgomarela sepheo sa "E re thepa e ntjha le dihlahiswa tse bohlale di ntlafatse boleng ba bophelo ba batho", sebetsa le balekane ba hodimo le ba tlase le basebetsi mmoho le indasteri ho kgothaletsa theknoloji e ntjha ya thepa e bolokehileng le e tala ya maemo a lefatshe, Lefatshe la dipalangwang le bohlale le sebetsang hantle, le thusang ntshetsopele ya boleng bo hodimo ya indasteri ya dipalangwang tsa diterene ya China.

Nako ea poso: Phupu-05-2021