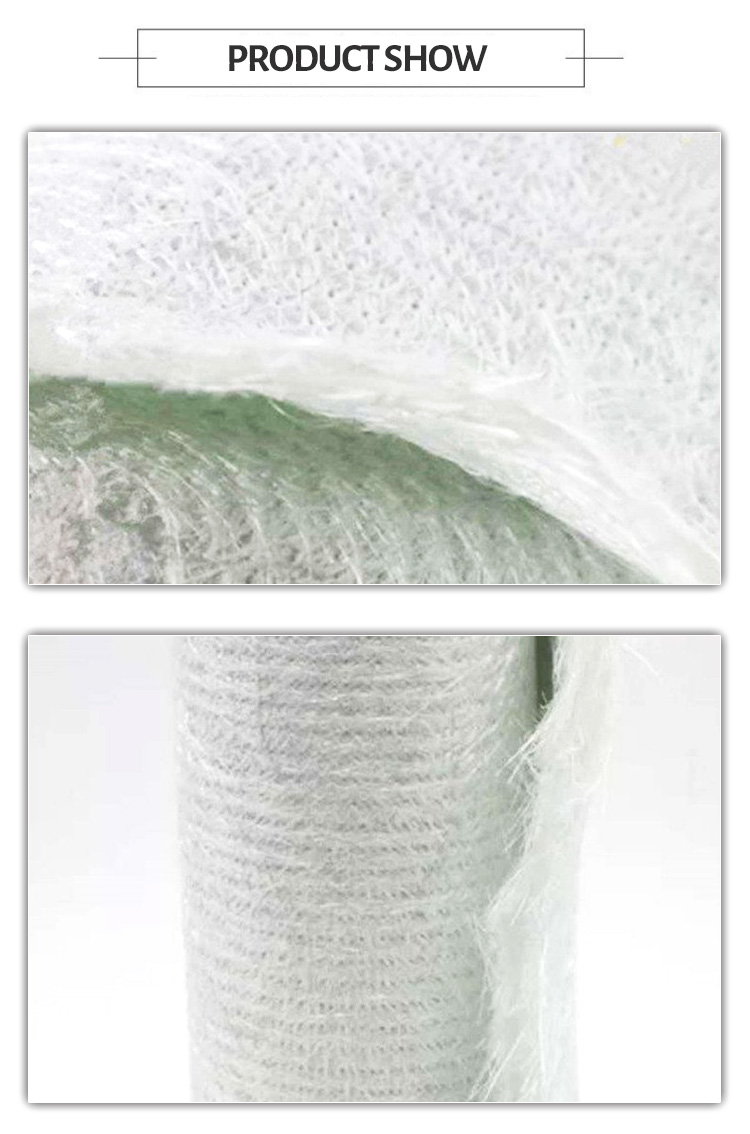

Mat ea mantlha ea fiberglass

Tlhaloso ea Sehlahisoa:

Moqomo oa mantlha ke thepa e ncha, e entsoeng ka motheo o sa lohiloeng oa maiketsetso, o kenngoeng pakeng tsa mekhahlelo e 'meli ea likhoele tsa khalase tse khaotsoeng kapa lera le le leng la likhoele tsa khalase tse khaotsoeng le lera le leng la lesela le nang le mahlakore a mangata/le lohiloeng. E sebelisoa haholo bakeng sa ts'ebetso ea RTM, Vacuum Forming, Molding, Ented Molding le SRIM Molding, e sebelisoang sekepeng sa FRP, koloing, sefofaneng, phanele, jj.

Litlhaloso tsa Sehlahisoa:

| Tlhaloso | Boima bohle (gsm) | Ho kheloha (%) | Tekanyo ea 0 (gsm) | Dik'hilograma tse 90 (gsm) | CSM (gsm) | Core (gsm) | CSM (gsm) | Khoele ea ho Roka (gsm) |

| BH-CS150/130/150 | 440 | ± 7 | - | - | 150 | 130 | 150 | 10 |

| BH-CS300/180/300 | 790 | ± 7 | - | - | 300 | 180 | 300 | 10 |

| BH-CS450/180/450 | 1090 | ± 7 | - | - | 450 | 180 | 450 | 10 |

| BH-CS600/250/600 | 1460 | +7 | - | - | 600 | 250 | 600 | 10 |

| BH-CS1100/200/1100 | 2410 | ± 7 | - | - | 1100 | 200 | 1100 | 10 |

| BH-300/L1/300 | 710 | ± 7 | - | - | 300 | 100 | 300 | 10 |

| BH-450/L1/450 | 1010 | ± 7 | - | - | 450 | 100 | 450 | 10 |

| BH-600/L2/600 | 1410 | ± 7 | - | - | 600 | 200 | 600 | 10 |

| BH-LT600/180/300 | 1090 | ± 7 | 336 | 264 | 180 | 300 | 10 | |

| BH-LT600/180/600 | 1390 | ± 7 | 336 | 264 | 180 | 600 | 10 |

Tlhokomeliso: XT1 e bolela lera le le leng la letlooeng la phallo, XT2 e bolela lera tse 2 tsa letlooeng la phallo. Ntle le litlhaloso tse tloaelehileng tse kaholimo, lera tse ling (4-5 Iayers) le lisebelisoa tse ling tsa mantlha li ka kopanngoa ho latela kopo ea moreki.

Joalo ka masela a lohiloeng a roving/multiaxial + motheo + lera le khaotsoeng (mahlakore a le mong/a mabeli).

Likarolo tsa Sehlahisoa:

1. Kaho ea sandwich e ka eketsa matla le botenya ba sehlahisoa;

2. ho kenella ho hoholo ha motheo wa maiketsetso, di-resin tse ntle tse metsi, lebelo le potlakileng la ho tiisa;

3. Tshebetso e phahameng ea mechini, e bonolo ho e sebetsa;

4. Ho bonolo ho bopa ka dikhutlo le dibopeho tse rarahaneng haholoanyane;

5. ho mamella le ho hatelloa ha karolo ea mantlha, ho ikamahanya le botenya bo fapaneng ba likarolo;

6. ho hloka binder ea lik'hemik'hale bakeng sa ho kenngoa hantle ha matlafatso.

Kopo ea Sehlahisoa:

E sebelisoa haholo ho bōpeng ka ho kobeha ho etsa liphaephe tse nang le lehlabathe la FRP (ho kenya liphaephe), li-hull tsa likepe tsa FRP, mahare a turbine ea moea, matlafatso ea marokho a annular, matlafatso e tšekaletseng ea liprofaele tse senyehileng, le lisebelisoa tsa lipapali, jj. indastering.