Thermoplastic e Matlafalitsoeng ea Fibeglass Assembeld e tsamaeang ka PBT/PET, Resin ea ABS bakeng sa Likarolo tsa FRP

Ho thekesela ho kopantsoeng bakeng sa thermoplastic ho koahetsoe ka boholo bo thehiloeng ho silane bo lumellanang le litsamaiso tse ngata tsa resin tse kang PP, AS/ABS, haholo-holo ho matlafatsa PA bakeng sa ho hanela hydrolysis hantle.

Likaroloana:

- Thepa e ntle ea mechini le ho hanela hydrolysis bakeng sa PA

- Bokaholimo bo benyang ba sehlahisoa se kopaneng se se nang faeba bo senotsoe.

- Boreleli le bo bobebe bakeng sa sepakapaka se setle sa ho sebetsa.

- Botenya ba liner bo tšoanang bakeng sa lihlahisoa tsa ho qetela tse nang le khalase e tsitsitseng.

- E lumellana le sistimi e mengata ea resin joalo ka PP, AS/ABS.

| Boitsebiso | |

| Mofuta oa Khalase | E |

| Ho Tsamaea ho Kopantsoeng | R |

| Bophara ba filthara, μm | 11,13,14 |

| Botenya ba mola, tex | 2000 |

| Li-parameter tsa Tekheniki | |||

| Botenya ba Mothapo (%) | Mongobo (%) | Boholo ba Dikahare (%) | Ho satalla (mm) |

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ± 5 | ≤0.10 | 0.90±0.15 | 130±20 |

Ho Ntša le ho Kenajkarolo Mekhoa

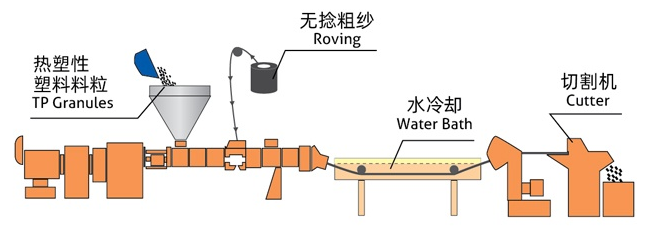

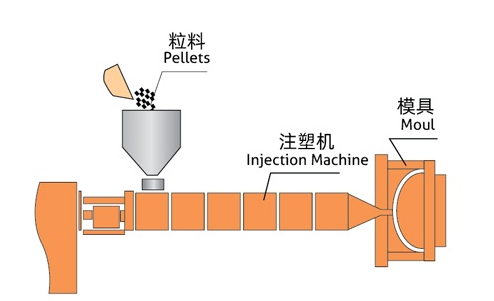

Di-reinforcement (kgalase ya faeba e tsamayang) le resin ya thermoplastic di kopanngwa ka hara extruder Kamora ho phodisa, di kgaolwa ka di-pellet tsa thermoplastic tse matlafaditsweng. Di-pellet di fepuwa ka hara mochini o entsweng ka ente ho etsa dikarolo tse fedisitsweng.

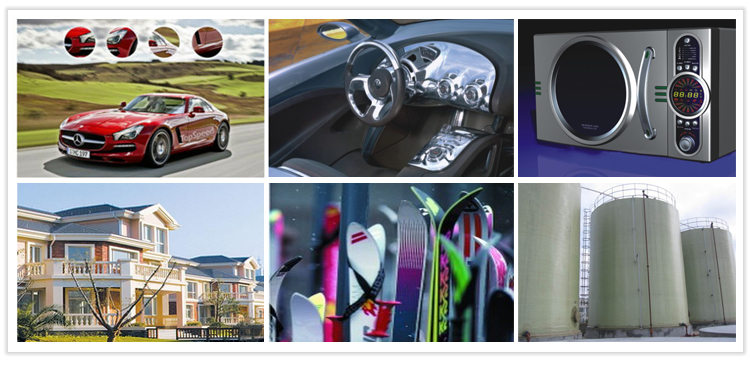

Kopo

Li-Thermoplastic tse kopantsoeng ka khalase ea elektroniki hangata li etselitsoe mokhoa oa ho ntša li-screw tse peli ho etsa li-granule tsa thermoplastic. Lisebelisoa tsa bohlokoa li kenyelletsa likarolo tsa ho tiisa tsela ea terene, likarolo tsa likoloi, lits'ebetso tsa motlakase le tsa elektroniki.