Ho Sokoloha ka ho Otloloha Bakeng sa ho Sokoloha ha Filament

Ho Sokoloha ka ho Otloloha Bakeng sa ho Sokoloha ha Filament

Ho Roving ka ho Otloloha bakeng sa ho kobeha ha Filament, ho tsamaisana le polyester e sa tlalang, polyurethane, vinyl ester, epoxy le phenolic resins.

Likaroloana

●Ts'ebetso e ntle ea ts'ebetso le fuzz e tlase

●Compatibillty le litsamaiso tse ngata tsa resin

●Thepa e ntle ea mechini

●E kolobile ka botlalo le ka potlako

● Ho hanyetsa serame sa asiti hantle haholo

Kopo

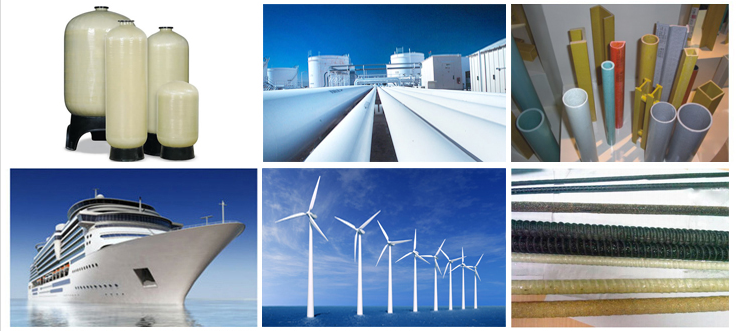

Mesebetsi e meholo e kenyelletsa tlhahiso ea liphaephe tsa FRP tsa bophara bo fapaneng, liphaephe tse nang le khatello e phahameng bakeng sa phetoho ea peterole, lijana tsa khatello, litanka tsa polokelo, le thepa ea ho futhumatsa e kang lithupa tsa thuso le tube ea ho futhumatsa.

Lethathamo la Lihlahisoa

| Ntho | Botenya ba Mothapo | Ho lumellana ha Resin | Likaroloana | Tšebeliso ea ho Qetela |

| BHFW-01D | 1200,2000,2400 | EP | E lumellana le resin ea epoxy, e etselitsoeng ts'ebetso ea ho kobeha ha filament tlas'a khatello e phahameng | e sebelisoa e le matlafatso ho etsa phaephe ea khatello e phahameng bakeng sa phetiso ea peterole |

| BHFW-02D | 2000 | Polyurethane | E lumellana le resin ea epoxy, e etselitsoeng ts'ebetso ea ho kobeha ha filament tlas'a khatello e phahameng | E sebelisetsoa ho etsa lithupa tsa motlakase |

| BHFW-03D | 200-9600 | UP,VE,EP | E lumellana le li-resin; Fuzz e tlase; Thepa e ntle ea ts'ebetso; Matla a phahameng a mechini a sehlahisoa se kopaneng | E sebelisoa ho etsa litanka tsa polokelo le liphaephe tsa FRP tsa khatello ea medial bakeng sa phetiso ea metsi le ts'enyeho ea lik'hemik'hale |

| BHFW-04D | 1200,2400 | EP | Thepa e ntle ea motlakase | E sebelisoa ho etsa phaephe ea ho thibela e se nang letho |

| BHFW-05D | 200-9600 | UP,VE,EP | E lumellana le li-resin; Litšobotsi tse ntle tsa mechini tsa sehlahisoa se kopaneng | E sebelisoa ho etsa liphaephe tse tloaelehileng tsa FRP tse hanelang khatello le litanka tsa polokelo |

| BHFW-06D | 735 | HOlimo, VE, HOlimo | Tshebetso e ntle haholo; Khanyetso e ntle haholo ea ts'enyeho ea lik'hemik'hale, joalo ka oli e tala le khase H2S ts'enyeho jj; Khanyetso e ntle haholo ea ho khohlela | E etselitsoe RTP (phaephe ea thermoplastics ea ho matlafatsa) e kobehang ka filament e hlokang ho hanyetsa asiti le ho hanyetsa ho khohlela. E loketse ho sebelisoa lits'ebetsong tsa liphaephe tse ka qhekelloang |

| BHFW-07D | 300-2400 | EP | E lumellana le resin ea epoxy; Fuzz e tlase; E etselitsoe ts'ebetso ea ho kobeha ha filament tlas'a khatello e tlase | e sebediswa e le ho matlafatsa sejana sa kgatello le phaephe ya FRP e hanyetsanang le kgatello e phahameng le e mahareng bakeng sa phetiso ya metsi |

| Boitsebiso | |||||||

| Mofuta oa Khalase | E | ||||||

| Ho Sokoloha ka ho Otloloha | R | ||||||

| Bophara ba filthara, μm | 13 | 16 | 17 | 17 | 22 | 24 | 31 |

| Botenya ba mola, tex | 300 | 200 400 | 600 735 | 1100 1200 | 2200 | 2400 4800 | 9600 |

| Li-parameter tsa Tekheniki | |||

| Botenya ba Mothapo (%) | Mongobo (%) | Boholo ba Dikahare (%) | Matla a ho Robeha (N/Tex) |

| ISO1889 | ISO3344 | ISO1887 | IS03341 |

| ± 5 | ≤0.10 | 0.55±0.15 | ≥0.40 |

Mokhoa oa ho Phetla Likhoele tsa Filament

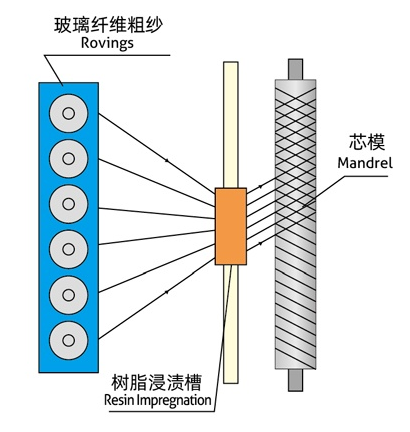

Ho Phetla ha Filament ea Setso

Mokhoeng oa ho kobeha ha khoele, likhoele tse tsoelang pele tsa fiber ea khalase e kenngoeng ka resin li tlamelloa tlas'a khatello holim'a mandrel ka mekhoa e nepahetseng ea jeometri ho haha karolo e tla lokisoa ho etsa likarolo tse felileng.

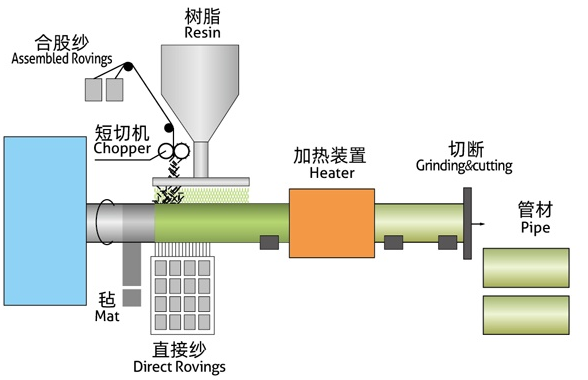

Ho Tsoela Pele ho Phetla Lifilamente

Mealo e mengata ea laminate, e entsoeng ka resin, khalase ea matlafatso le thepa e 'ngoe e sebelisoa ho mandrel e potolohang, e entsoeng ka lebanta la tšepe le tsoelang pele le tsamaeang ka mokhoa o tsoelang pele ka ho sisinyeha ha sekerefu sa kork. Karolo e kopaneng e futhumatsoa le ho hloekisoa sebakeng sa eona ha mandrel e ntse e tsamaea ka har'a mohala ebe e khaoloa ka bolelele bo itseng ka sakha e khaotsoeng e tsamaeang.