Lilemong tse peli tse fetileng, ka lebaka la phetoho ea theknoloji ea thepa ea tšireletso e sa sebetseng hantle ea mocheso bakeng sa libeteri tse ncha tsa matla, bareki ba ntse ba batla ts'ebetso e ntlafalitsoeng ea ho thibela mocheso hammoho le khanyetso ea ho thibela ho bola e kang ea ceramic - thepa ea bohlokoa bakeng sa ho mamella tšusumetso ea lelakabe.

Mohlala, lits'ebetso tse ling li hloka mocheso oa ho tlosa malakabe ka lehlakoreng le ka pele oa 1200°C ha li ntse li boloka mocheso oa lehlakore le ka morao o le ka tlase ho 300°C. Lisebelisoang tsa sefofane, ho tlosa malakabe ka lehlakoreng le ka pele la acetylene ho 3000°C ho hloka mocheso oa lehlakore le ka morao o ka tlase ho 150°C. Ntho e thata ka ho fetisisa ke tlhoko e phahameng ea ts'ebetso ea khatello ho foam ea silicone e entsoeng ka ceramic, e hlokang sete e tlase ea khatello le ho boloka mocheso o motle oa ho thibela mocheso mochesong o phahameng. Lisebelisoa tsena ka kakaretso li hlahisa litlhoko tse ncha tsa ho thibela mocheso bakeng sa theknoloji ea ceramicization.

Litlhoko tse khethehileng tsa ts'ebetso (bakeng sa litšupiso feela):

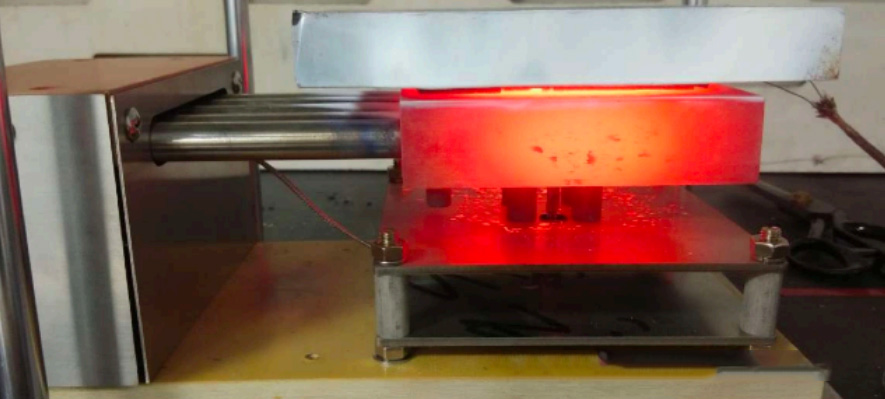

Futhumatsa sampole sethaleng sa ho futhumatsa joalokaha ho bontšitsoe ka tlase. Boloka sebaka se chesang ho 600 ± 25 °C metsotso e 10. Sebelisa khatello ea 0.8±0.05 MPa mochesong oa teko, ho netefatsa hore mocheso oa sebaka se ka morao o lula o le ka tlase ho 200°C.

Kajeno, re akaretsa lintlha tsena bakeng sa litšupiso tsa hau.

1. Silikate ea Kalsiamo ea Maiketsetso – Setlolo se Tšoeu sa ho Tlatsa sa Thermal Insulation

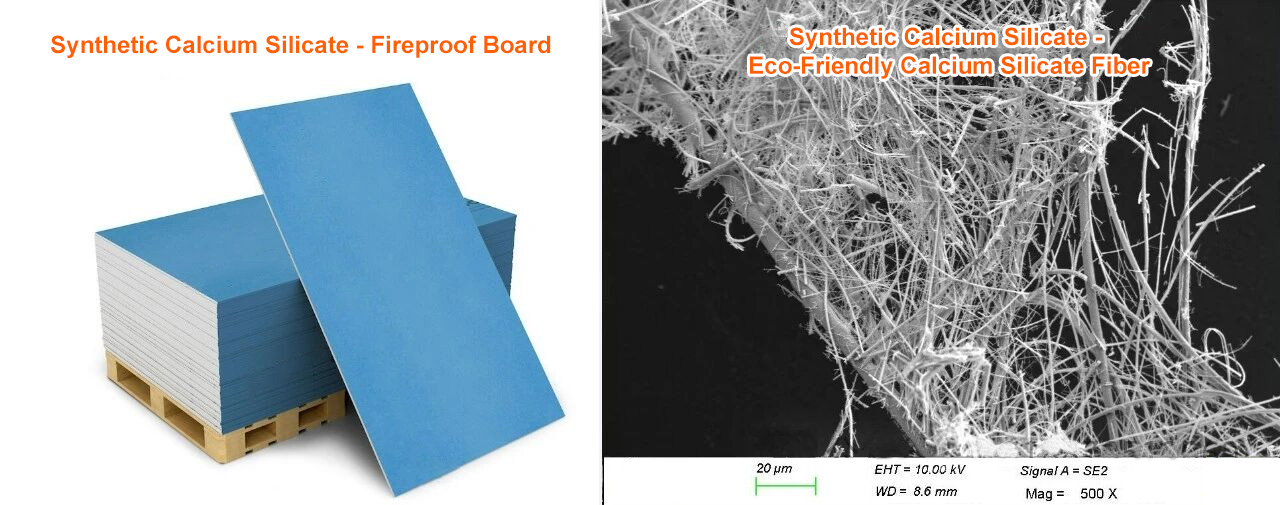

Silikate ea calcium ea maiketsetso e teng ka mefuta e 'meli: meaho e nang le masoba/selika le meaho e nang le likhoele tse kang ceramic-fiber. Ho sa tsotellehe liphapang tsa meaho le tsa sebopeho, ka bobeli li sebetsa e le li-filler tse tšoeu tse ntle tse thibelang mocheso tse hanelang mocheso o phahameng.

Faeba ea silicate ea calcium ea maiketsetso ke e sireletsang tikoloho lethepa e sireletsehileng ea ho thibela mochesoka khanyetso e phahameng ea mocheso ho fihlela ho 1200-1260°C. Phofo ea faeba ea silicate ea calcium e entsoeng ka mokhoa o khethehileng e ka sebetsa e le thepa e matlafalitsoeng ke faeba bakeng sa ho thibela mocheso o phahameng.

Khalsiamo silicate e entsoeng ka maiketsetso e nang le masoba kapa e chitja, e na le bosweu bo phahameng, bonolo ba ho e kenya, sebopeho se ruileng sa nanoporous, boleng ba ho monya oli bo phahameng haholo (ho fihlela ho 400 kapa ho feta), le tokoloho ho libolo tsa slag kapa likaroloana tse kholo. E pakile ts'ebeliso ho insulation e hanelang mocheso o phahameng le liphanele tse sa cheng, e bonts'a ho khoneha ha ho kenyelletsoa linthong tse hanelang ablation tse entsoeng ka ceramic ho fana ka insulation ea mocheso o phahameng.

Lisebelisoa tse ling li kenyelletsa: li-additives tsa metsi a phofshoana, li-coat tsa phofo tse sireletsang mocheso o phahameng, li-carriers tsa perfume absorbent, li-anti-drip agents, thepa ea brake pad friction, rabara ea silicone e nang le khatello e tlase le oli ea silicone e ipolaeang, li-filler tsa pampiri, jj.

2. Silicate ea Aluminium e nang le Metsi e Meholo ea Magnesium- Ho kenya mocheso le ho hanyetsa mocheso o phahameng

Diminerale ena e silicate e hloka calcination e phahameng mochesong o phahameng ka ho hanyetsa ho fihlela ho 1200°C. Haholo-holo e entsoe ka silicate ea aluminium ea magnesium, e na le sebopeho se nang le masoba a mangata se fanang ka matla a ho kopanya a phahameng, ho hanyetsa metsi hantle, nako e telele ea ho hanyetsa, le katleho e phahameng ea litšenyehelo.

Mesebetsi ea eona ea mantlha e kenyelletsa ho kenya mocheso o phahameng, phokotso ea bongata, ho ntlafala ha ho hanyetsa mocheso, le ho ntlafala ha ho thibela ho bola ha mocheso le ho kenya mocheso bakeng sa likarolo tsa khabone le likheo. Litšebeliso li kenyelletsa thepa ea ho kenya mocheso e entsoeng ka ceramic, liphahlo tse sa cheng tsa boleng bo holimo, thepa ea ho kenya mocheso e thibelang ho bola ha mocheso, le thepa ea ho kenya mocheso e thibelang ho bola ha mocheso.

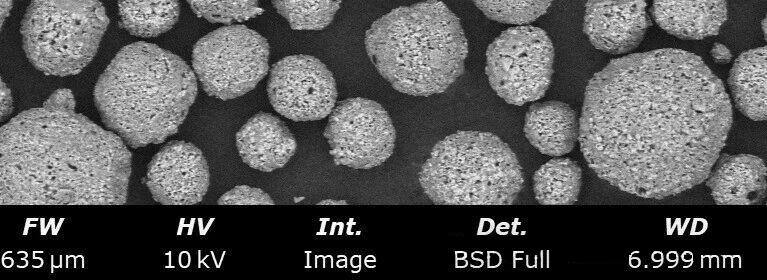

3. Li-Microspheres tsa Ceramic - Khanyetso ea Mocheso o Phahameng, Ho Sireletsa Mocheso, Matla a Khatello

Ha ho pelaelo hore li-microsphere tsa khalase tse se nang letho ke thepa e ntle ea ho thibela mocheso, empa ho hanyetsa mocheso ha tsona ha hoa lekana. Lintlha tsa tsona tsa ho nolofatsa hangata li tloha ho 650-800°C, 'me mocheso oa ho qhibiliha o fihla ho 1200-1300°C. Sena se fokotsa ts'ebeliso ea tsona maemong a ho thibela mocheso a mocheso o tlase. Tlas'a maemo a mocheso o phahameng joalo ka ho kenngoa ha ceramic le ho hanyetsa ho tlosoa ha mocheso, ha li sebetse hantle.

Li-microsphere tsa rona tsa ceramic tse se nang letho li rarolla bothata bona. Haholo-holo li entsoe ka aluminosilicate, li fana ka khanyetso ea mocheso o phahameng, ho kenya mocheso o ikhethang, ho hanyetsa mocheso ho phahameng, le khanyetso e phahameng ea ho robeha. Lisebelisoa li kenyelletsa li-additives tsa ceramic tsa silicone, thepa ea ho kenya mocheso o hanyetsang, li-additives tsa mocheso o phahameng bakeng sa li-resin tsa organic, le li-additives tsa rabara tse hanyetsang mocheso o phahameng. Makala a bohlokoa a kenyelletsa lifofane, lipatlisiso tsa botebo ba leoatle, thepa e kopaneng, liphahlo, ho kenya mocheso o thibelang mocheso, indasteri ea peterole le thepa ea ho kenya mocheso.

Ena ke phofo e nyenyane e chitja e sa cheseng e hanelang mocheso haholo e bonolo haholo ho e kenyelletsa (ho fapana le li-microspheres tsa khalase tse se nang letho, tse hlokang ho hasana pele kapa ho fetoloa bakeng sa ho eketsa hantle) 'me li na le khanyetso e ntle ea mapetso. Tšobotsi ea eona e ikhethang ke hore ke thepa e bulehileng holim'a metsi e sa phaphametseng holim'a metsi, e leng se etsang hore ho be bonolo ho e teteanya le ho lula.

Ho phaella moo, ho boletsoe ka bokhutšoanyanephofo ea airgel—thepa ea maiketsetso ea ho thibela silika e nang le masoba. Airgel e tsejoa haholo e le sesebelisoa se setle sa ho thibela mocheso, se fumanehang ka mefuta e sa rateng metsi/e sa rateng metsi. Sena se lumella khetho ea mekhoa e nepahetseng ea kalafo e thehiloeng holim'a li-substrate tsa resin, ho sebetsana le liphephetso tsa phofo ea airgel tsa ho hasana ho bobebe haholo le ho ntlafatsa ho qhalana ha eona. Li-paste tsa airgel tse thehiloeng metsing le tsona lia fumaneha bakeng sa ho kenyelletsoa habonolo lits'ebetsong tsa metsi.

Litšobotsi tse ikhethang tsa ho thibela mocheso tse nang le masoba tsa phofo ea airgel li nolofalletsa ts'ebeliso ea eona ho: – Lijari tsa rabara le tsa polasetiki tse tlatsetsang – Lisebelisoa tsa ho thibela mocheso bakeng sa libeteri tse ncha tsa matla – Liaparo tsa ho thibela mocheso tsa moaho – Lifaeba tsa masela tsa ho thibela mocheso – Liphanele tsa ho thibela mocheso tsa moaho – Liaparo tsa ho thibela mocheso tse sa cheng – Likhomaretsi tsa ho thibela mocheso.

Nako ea poso: Loetse-22-2025