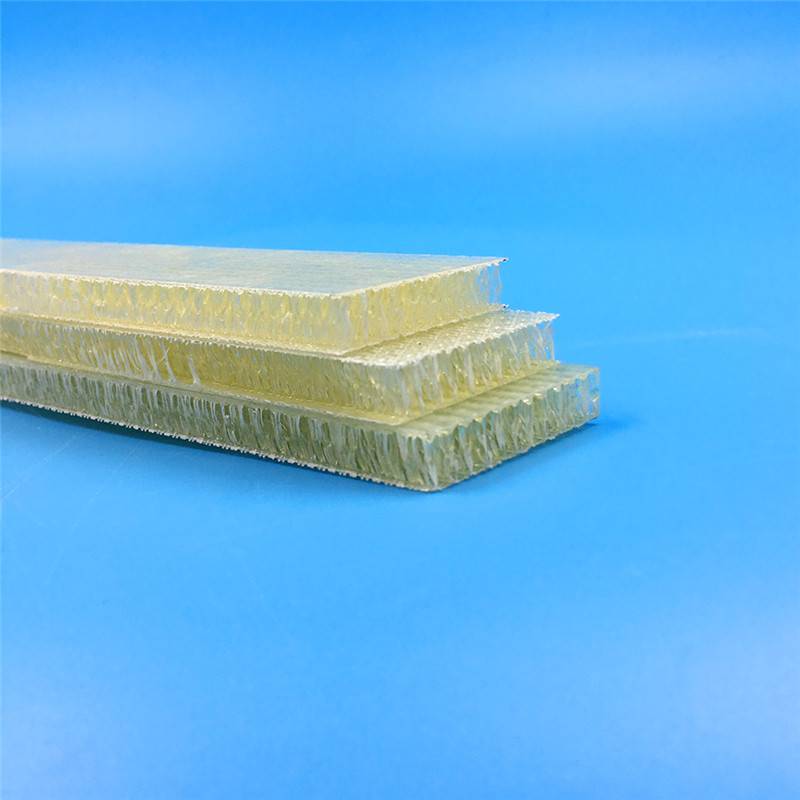

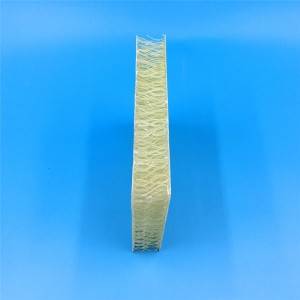

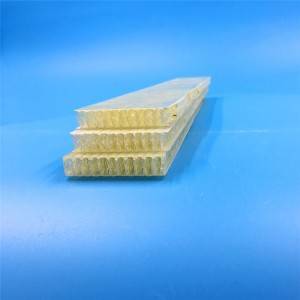

Phanele ea 3D FRP e nang le resin

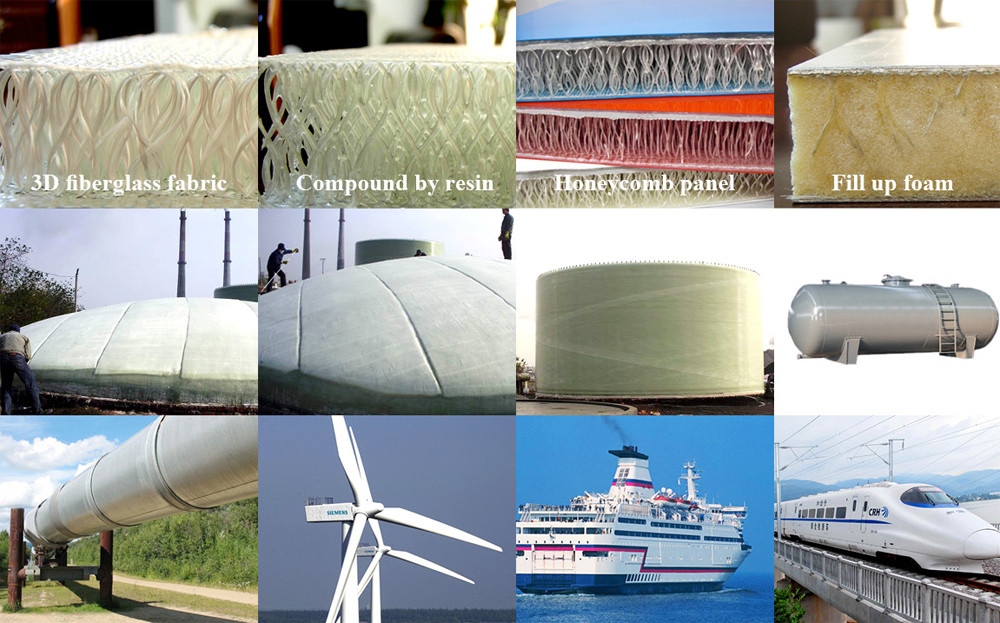

Lesela le lohiloeng la Fiberglass la 3-D le ka kopanngoa le li-resin tse fapaneng (polyester, Epoxy, Phenolic le jj), ebe sehlahisoa sa ho qetela ke phanele ea 3D e kopantsoeng.

Molemo

1. boima bo bobebe ba bur matla a phahameng

2. Khanyetso e kholo khahlanong le ho qhekelloa ha lehare

3. Moralo o phahameng – ho tenyetseha

4. Sebaka pakeng tsa mealo ka bobeli ea deck e ka ba le mesebetsi e mengata (E kentsoe ka li-sensor le lithapo kapa e tšetsoe ka foam)

5. Mokhoa o bonolo le o sebetsang oa ho lamination

6. Ho thibela mocheso le ho thibela molumo, Ho thibela mollo, Ho ka fetisoang maqhubu

Kopo

Tlhaloso

| Bophahamo ba Pilara | mm | 4.0 | 6.0 | 8.0 | 10.0 | 12.0 | 15.0 | 20.0 | |

| Botenya ba ho kobeha | motso/10cm | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Boima ba Weft | motso/10cm | 96 | 96 | 96 | 96 | 96 | 96 | 96 | |

| Botenya ba Sefahleho | Masela a spacer a 3-D | kg/m2 | 0.96 | 1.01 | 1.12 | 1.24 | 1.37 | 1.52 | 1.72 |

| Masela a spacer a 3-D le kaho ea sandwich | kg/m2 | 1.88 | 2.05 | 2.18 | 2.45 | 2.64 | 2.85 | 3.16 | |

| Matla a Tensile a Folete | MPa | 7.5 | 7.0 | 5.1 | 4.0 | 3.2 | 2.1 | 0.9 | |

| Matla a Khatello a Foreimi | MPa | 8.2 | 7.3 | 3.8 | 3.3 | 2.5 | 2.0 | 1.2 | |

| Modulus e hatellang ka tsela e otlolohileng | MPa | 27.4 | 41.1 | 32.5 | 43.4 | 35.1 | 30.1 | 26.3 | |

| Matla a ho beola | Koahela | MPa | 2.9 | 2.5 | 1.3 | 0.9 | 0.8 | 0.6 | 0.3 |

| Boea | MPa | 6.0 | 4.1 | 2.3 | 1.5 | 1.3 | 1.1 | 0.9 | |

| Modulus ea ho kuta | Koahela | MPa | 7.2 | 6.9 | 5.4 | 4.3 | 2.6 | 2.1 | 1.8 |

| Boea | MPa | 9.0 | 8.7 | 8.5 | 7.8 | 4.7 | 4.2 | 3.1 | |

| Ho Tiea ha ho Kobeha | Koahela | N.m2 | 1.1 | 1.9 | 3.3 | 9.5 | 13.5 | 21.3 | 32.0 |

| Boea | N.m2 | 2.8 | 4.9 | 8.1 | 14.2 | 18.2 | 26.1 | 55.8 | |

Ela Hloko: Lenane la tshebetso le ka hodimo bakeng sa merero ya tlhahisoleseding feela, ho latela ditlhoko tsa tshebetso tsa mosebedisi, sebopeho sa matlafatso ya lesela la spacer sa 3D se ka etswa.